As a pipeline engineer, the recent agreement between OQ Gas Networks (OQGN) and Fluxys is more than just a headline, it’s a landmark step forward in the evolution of energy infrastructure in the Middle East. The signing of a Memorandum of Understanding (MoU) between the two companies marks a strategic shift toward low-carbon technologies, with a focus on hydrogen and carbon dioxide (CO₂) transport and storage.

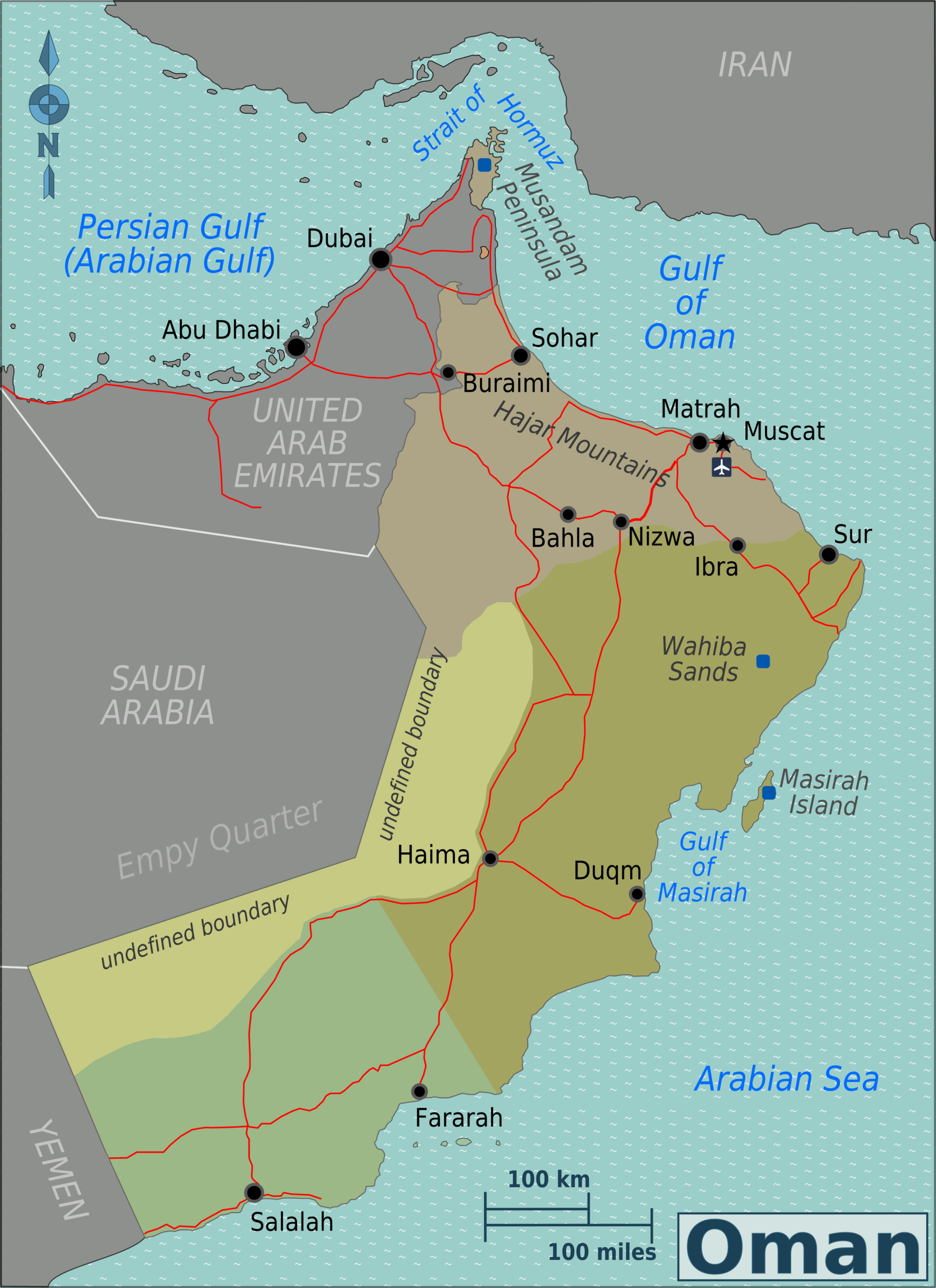

This collaboration comes at a crucial time, as Oman positions itself to become a key player in the global energy transition. With OQGN owning and operating Oman’s natural gas transmission network, and Fluxys bringing international experience in hydrogen and CO₂ transport systems, this partnership holds enormous engineering potential.

Technical Significance

From an engineering standpoint, the shift from conventional natural gas pipelines to hydrogen-compatible systems is a serious undertaking. Hydrogen’s small molecular size and higher diffusivity pose unique challenges, including material compatibility, embrittlement risks, and leak detection.

Developing a dual-purpose or repurposed pipeline system that can handle both hydrogen and CO₂ safely and efficiently is a key technical challenge. CO₂ pipelines, particularly for carbon capture and storage (CCS), require careful design considerations around phase behavior (gas, liquid, or supercritical), pressure control, and impurity management.

This MoU signals that both OQGN and Fluxys are not only aligned on business strategy but also willing to invest in overcoming these technical hurdles, especially in a region with high solar and wind potential like Oman, which is ideal for producing green hydrogen.

Engineering Roadmap

The partnership is likely to follow a multi-phase roadmap:

- Feasibility and Front-End Engineering Design (FEED): Identification of viable routes for hydrogen and CO₂ pipelines, evaluation of existing assets for repurposing, and initial safety/risk assessments.

- Material Testing & Specification Development: Selection of pipeline materials resistant to hydrogen embrittlement and CO₂ corrosion, with special attention to welding, joining, and coating technologies.

- Compressor and Valve Adaptation: Design and testing of components capable of handling lower-density hydrogen and high-pressure CO₂, including blowdown systems and emergency shut-off protocols.

- Digital Infrastructure & Monitoring: Integration of SCADA systems with advanced leak detection, flow metering for hydrogen blends, and real-time integrity monitoring.

A New Era for Pipeline Engineering

For those of us in the pipeline sector, this partnership is a case study in the future of energy transport. It’s not just about replacing molecules in the pipe, it’s about adapting entire infrastructure ecosystems to safely and reliably handle the fuels of tomorrow.

As engineers, we’re looking at a significant evolution in how pipelines are designed, maintained, and monitored. This project has the potential to become a regional model for integrated hydrogen and CO₂ pipeline infrastructure, setting technical benchmarks for future projects worldwide.

Final Thoughts

The OQGN–Fluxys agreement is a pivotal development for engineers working on the front lines of the energy transition. It’s a call to action for innovation in pipeline materials, system design, and operational protocols. As we move toward decarbonization, partnerships like this aren’t just strategic, they’re essential for building the infrastructure that the energy future demands.

—Written from the desk of a pipeline engineer watching the transition unfold, one joint weld at a time.