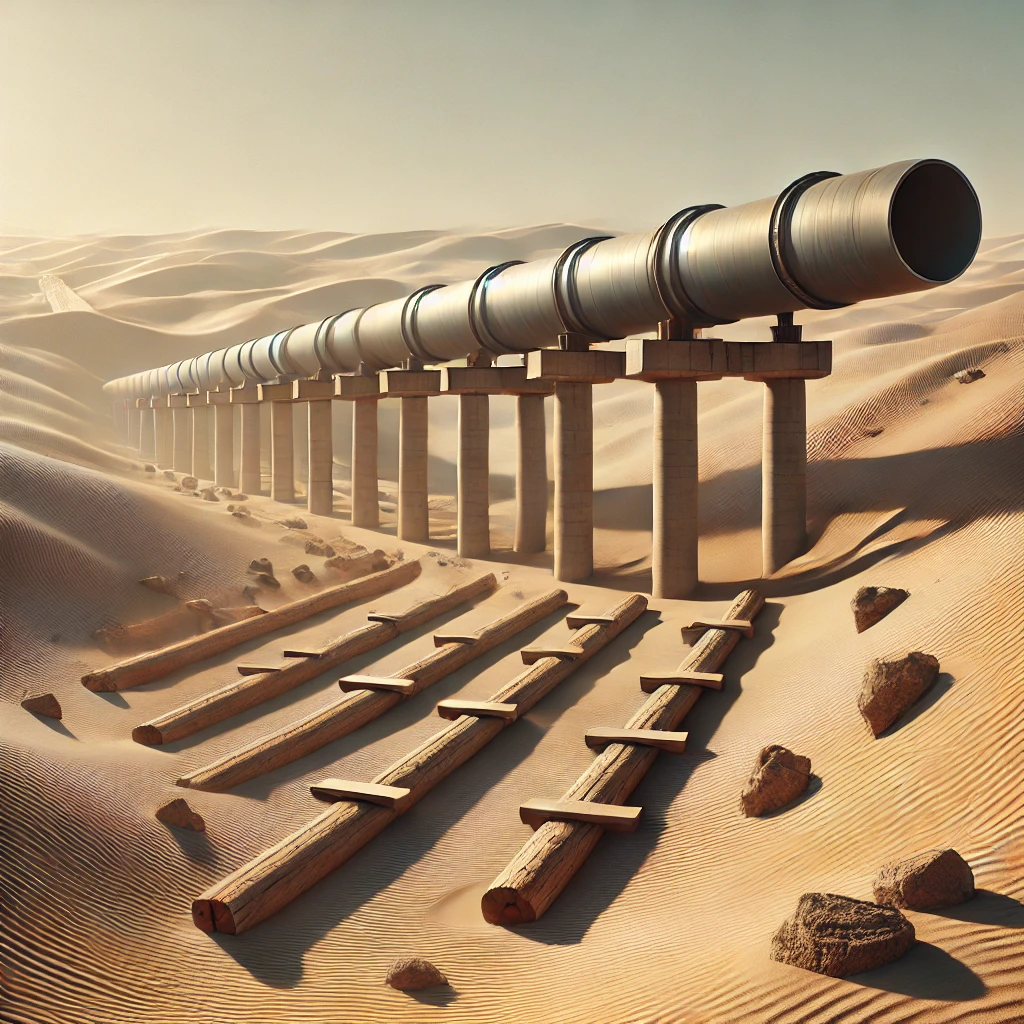

Pipe supports are crucial elements in piping systems, providing stability, reducing stress, and ensuring the safe operation of the entire system. Proper selection and design of pipe supports are essential to maintaining the structural integrity of pipelines, especially in complex environments or systems involving high temperatures, pressures, or dynamic forces. This article delves into the principles of pipe support selection and the design of special pipe supports, highlighting their importance in modern engineering applications.

Principles of Pipe Support Selection

Selecting the appropriate pipe support is a critical step in the design process. The selection is based on various factors, including the pipe’s material, size, operating conditions, and the specific requirements of the piping system. The following are the key principles to consider:

1. Load Considerations

Pipe supports must be capable of carrying the loads imposed on the piping system. These loads include:

- Dead Loads: The weight of the pipe itself, along with the contents within the pipe, is a significant consideration. Supports must be designed to bear this static load consistently.

- Live Loads: These are dynamic forces acting on the pipe, including fluid flow, vibrations, and external forces such as wind or seismic activity. Supports must accommodate these fluctuating loads without compromising the integrity of the piping system.

- Thermal Loads: Thermal expansion and contraction due to temperature changes can impose additional stresses on the piping system. Supports must be designed to allow for this movement while still maintaining structural stability.

2. Type of Support

The type of support used depends on the specific requirements of the piping system. Common types include:

- Hangers: Used to support piping from above, hangers are often adjustable and allow for vertical movement. They are ideal for systems where thermal expansion is significant.

- Saddles: These are used to support the pipe from below, distributing the load over a larger area. Saddles are typically used in systems with large-diameter pipes or where the load is particularly heavy.

- Anchors: Anchors are rigid supports that prevent movement in any direction. They are used where it is crucial to fix the position of the pipe, such as at changes in direction or where connections to equipment are made.

- Spring Supports: These supports accommodate vertical movement caused by thermal expansion while maintaining a constant load on the pipe. They are essential in systems with significant temperature fluctuations.

3. Environmental Considerations

The environment in which the piping system operates also influences the choice of support. For example:

- Corrosive Environments: In environments with high corrosion potential, supports must be made from corrosion-resistant materials, such as stainless steel, or be coated with protective materials to prevent degradation.

- High-Temperature Environments: Supports used in high-temperature environments must be designed to withstand the thermal stresses and material degradation that can occur at elevated temperatures.

4. Movement and Flexibility

Piping systems are subject to expansion, contraction, and other movements due to thermal effects and operational conditions. Supports must provide sufficient flexibility to accommodate these movements without causing excessive stress on the pipe or the support itself. This is particularly important in systems that transport high-temperature fluids or where significant temperature fluctuations occur.

Design of Special Pipe Supports

In some cases, standard pipe supports may not meet the specific requirements of a piping system. In such scenarios, custom or special pipe supports are designed to address unique challenges. The design of these supports requires a thorough understanding of the forces acting on the piping system, the materials used, and the environmental conditions. Below are some of the considerations and approaches in designing special pipe supports.

1. Custom Load-Bearing Supports

For pipelines carrying exceptionally heavy loads, such as those in large industrial facilities, custom load-bearing supports may be necessary. These supports are designed to distribute the load evenly and prevent any localized stress points that could lead to failure.

- Base Plates and Gussets: These are often used to reinforce supports and ensure they can bear the load without deforming. Base plates distribute the load over a larger area, while gussets add rigidity to the support structure.

- Multi-Support Configurations: In some cases, multiple supports are used in conjunction to share the load. This configuration is particularly useful in long pipe runs where the weight and thermal expansion forces are significant.

2. Vibration and Dynamic Load Supports

Pipelines subjected to vibration, whether from fluid flow, machinery, or external forces, require special supports to mitigate the effects of these dynamic loads. Vibration can lead to fatigue and eventual failure of the piping system if not properly managed.

- Vibration Dampers: These are designed to absorb and dissipate energy from vibrations, reducing the stress on the piping system. They are typically used in conjunction with other supports to provide comprehensive protection.

- Snubbers: Snubbers are used to limit the movement of the piping system during dynamic events such as earthquakes. They allow for normal thermal movement but engage during sudden shifts to protect the piping from excessive displacement.

3. Thermal Expansion Supports

In systems where thermal expansion is a significant concern, specialized supports are designed to allow for controlled movement. This ensures that the piping system can expand and contract without imposing undue stress on the connections or supports.

- Constant Support Hangers: These are designed to maintain a constant supporting force on the pipe, regardless of its vertical movement. They are particularly useful in systems with large vertical displacements due to thermal expansion.

- Guided Supports: These allow for movement in one direction while restraining movement in others. Guided supports are essential in managing thermal expansion in long pipe runs, preventing lateral displacement while allowing longitudinal expansion.

4. Corrosion-Resistant Supports

In corrosive environments, the design of pipe supports must consider material selection and protective coatings to prevent degradation.

- Material Selection: Materials such as stainless steel, galvanized steel, or specialized alloys are often chosen for their corrosion resistance. The selection depends on the specific corrosive agents present in the environment.

- Coatings and Linings: Protective coatings, such as epoxy or polyurethane, can be applied to supports to provide an additional barrier against corrosion. These coatings are especially important in environments with high humidity, saltwater exposure, or chemical vapors.

Conclusion

The selection and design of pipe supports are critical components of pipeline engineering, ensuring the safe and efficient operation of piping systems. By carefully considering the load-bearing requirements, environmental conditions, and the specific needs of the piping system, engineers can design supports that not only maintain the structural integrity of the pipeline but also extend its operational life. In scenarios where standard supports are inadequate, the design of special pipe supports provides tailored solutions that address unique challenges, ensuring that the piping system operates reliably under all conditions. As piping systems become more complex and operate in more demanding environments, the importance of precise and innovative pipe support design continues to grow.