Hot tapping, also known as pressure tapping, is a crucial process in pipeline engineering that allows modifications or repairs to be made to an existing pipeline without shutting down the system. This technique is essential for industries where continuous operation is vital, such as oil and gas, water, and chemical processing. A successful hot tap operation requires careful planning and precise calculations to ensure safety, structural integrity, and minimal disruption to the flow of the substance within the pipeline. This article delves into the technical aspects of hot tap calculations, covering the principles, methods, and considerations that engineers must address to execute a safe and effective hot tap.

Introduction to Hot Tapping

Hot tapping is a method used to create a new branch connection to an existing pipeline or vessel while it remains in service. This process involves attaching a branch fitting to the existing line, cutting a hole into the pipe, and installing a valve, all while maintaining the integrity of the pipeline’s pressurized contents. Hot tapping eliminates the need to depressurize, drain, or purge the pipeline, which can be costly and time-consuming.

The key to a successful hot tap lies in the accurate calculation of various parameters that ensure the pipeline can safely accommodate the new connection and that the cutting process can be carried out without compromising the pipeline’s structural integrity.

Principles of Hot Tap Calculation

Hot tap calculations are governed by several principles that address the structural, thermal, and operational aspects of the pipeline and the hot tap procedure. The primary factors to consider include:

- Pipe Material and Thickness: The material and thickness of the pipeline determine its ability to withstand the pressure and temperature changes during the hot tap. Different materials have varying strengths and properties, which must be accounted for in the calculations.

- Operating Pressure and Temperature: The pressure and temperature of the fluid inside the pipeline affect the design and execution of the hot tap. High pressures and temperatures can increase the risk of failure, making it crucial to calculate the maximum allowable operating conditions.

- Stress Analysis: The addition of a new branch introduces additional stress to the pipeline, which must be analyzed to prevent structural failure. Stress analysis involves calculating the stress concentration factors, checking for potential fatigue issues, and ensuring that the pipeline can handle the new loads.

- Corrosion Allowance: Over time, pipelines can experience corrosion, which reduces their wall thickness and, consequently, their ability to withstand pressure. Hot tap calculations must include a corrosion allowance to ensure that the pipeline remains safe even after accounting for material loss.

- Flow Considerations: The flow rate of the fluid in the pipeline can impact the hot tap operation. Engineers must consider the flow velocity and the potential for pressure surges during the tapping process to avoid disturbances that could lead to accidents.

Steps in Hot Tap Calculation

To perform a hot tap calculation, engineers must follow a series of steps that ensure all relevant factors are considered and that the hot tap can be safely executed.

1. Determine the Pipeline Specifications

The first step in hot tap calculation is to gather all relevant data about the existing pipeline. This includes:

- Material properties: Identify the type of material used in the pipeline (e.g., carbon steel, stainless steel) and its mechanical properties, such as yield strength and tensile strength.

- Pipe dimensions: Measure the outer diameter (OD), inner diameter (ID), and wall thickness of the pipeline.

- Operating conditions: Determine the current operating pressure and temperature of the fluid within the pipeline.

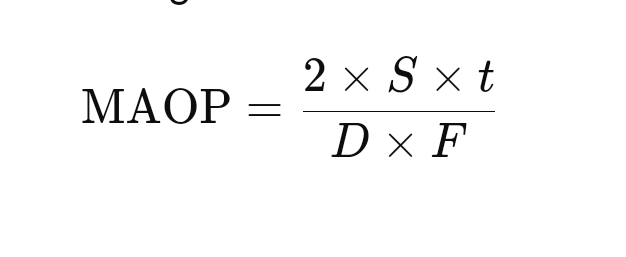

2. Calculate the Maximum Allowable Operating Pressure (MAOP)

The Maximum Allowable Operating Pressure (MAOP) is a critical parameter in hot tap calculations. It represents the maximum pressure that the pipeline can safely withstand, considering the material properties and the wall thickness.

The MAOP can be calculated using the Barlow’s formula:

Where:

- S = Specified Minimum Yield Strength (SMYS) of the pipeline material

- t = Nominal wall thickness of the pipeline

- D = Outside diameter of the pipeline

- F = Design factor (typically ranges from 0.4 to 0.72, depending on the location and service conditions)

The MAOP calculation ensures that the pipeline can handle the internal pressure after the hot tap is performed.

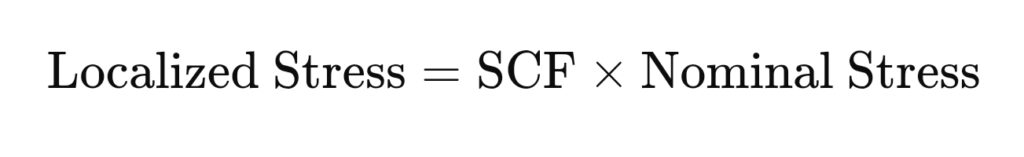

3. Determine the Stress Concentration Factor (SCF)

The addition of a branch connection creates stress concentrations in the pipeline, particularly around the welds and the area where the pipe wall is cut. The Stress Concentration Factor (SCF) accounts for these localized stresses.

The SCF can be determined using empirical formulas or by referring to stress concentration charts, which are based on the geometry of the hot tap connection. The SCF is used to calculate the localized stress:

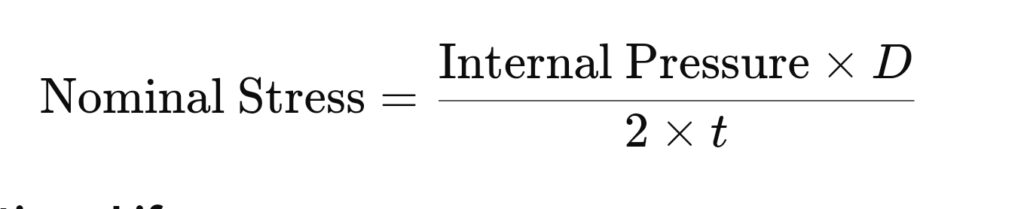

The nominal stress is typically calculated using the following formula:

4. Evaluate Fatigue Life

Pipelines are subject to cyclic loading due to pressure fluctuations, temperature changes, and other operational factors. The introduction of a hot tap can exacerbate these cyclic loads, leading to fatigue failure over time.

To evaluate the fatigue life, engineers use the stress range and the number of cycles the pipeline will experience. The fatigue life can be estimated using the S-N curve (Stress vs. Number of cycles) for the pipeline material. This curve provides a relationship between the applied stress and the number of cycles to failure.

5. Check for Corrosion Allowance

Corrosion is a common issue in pipelines, and it can reduce the wall thickness over time. When performing hot tap calculations, it’s essential to include a corrosion allowance, which accounts for the expected material loss over the pipeline’s operational life.

The corrosion allowance can be estimated based on the corrosion rate of the material in the specific environment and the expected service life of the pipeline. The effective wall thickness after accounting for corrosion is:

Effective Wall Thickness=Nominal Wall Thickness−Corrosion Allowance

6. Flow Analysis

The flow characteristics of the pipeline must be considered during the hot tap process. Engineers need to evaluate the flow velocity and the potential for pressure surges that could occur during the hot tap. High flow rates can increase the difficulty of the cutting process and create additional stresses on the pipeline.

Flow analysis can be performed using fluid dynamics principles, considering the Reynolds number, flow regime (laminar or turbulent), and pressure drop across the pipeline.

7. Determine the Cut Size and Tooling Requirements

The size of the cut to be made during the hot tap must be carefully calculated to ensure it matches the size of the branch connection. The tooling requirements, such as the hot tap machine and cutting tools, should be selected based on the pipe material, thickness, and diameter.

Engineers must also consider the type of valve to be installed, ensuring it can accommodate the flow conditions and pressure requirements of the pipeline.

Safety Considerations in Hot Tap Calculation

Safety is paramount in any hot tap operation. Several safety considerations must be addressed during the hot tap calculation process:

- Pressure Testing: Before performing the hot tap, pressure testing of the pipeline section is necessary to verify its integrity and ensure there are no existing leaks or weaknesses.

- Weld Quality: The quality of the welds used to attach the branch fitting to the pipeline is critical. Non-destructive testing (NDT) methods, such as radiography or ultrasonic testing, should be employed to inspect the welds for defects.

- Emergency Shutdown Procedures: In the event of an emergency during the hot tap, such as a leak or unexpected pressure surge, there must be procedures in place to quickly isolate and shut down the affected section of the pipeline.

- Personnel Safety: Hot tap operations should be carried out by trained personnel with appropriate protective equipment. Safety barriers and monitoring systems should be in place to protect workers from potential hazards.

Conclusion

Hot tapping is a complex and high-risk operation that requires meticulous planning and precise calculations. By following the principles outlined in this article, engineers can ensure that hot tap operations are performed safely and efficiently, minimizing the risk of accidents and maintaining the integrity of the pipeline.

The key aspects of hot tap calculations—material properties, stress analysis, corrosion allowance, and flow considerations—must be carefully evaluated to ensure a successful outcome. With the right approach and attention to detail, hot tapping can be a valuable tool for maintaining and modifying pipelines without disrupting critical operations.

In the rapidly evolving field of pipeline engineering, the ability to perform accurate and reliable hot tap calculations is essential for ensuring the safety and longevity of pipeline systems. As technology advances and new materials are developed, the methods and tools for hot tap calculations will continue to improve, offering even greater precision and safety in the future.