Introduction to Finite Element Analysis (FEA)

The Finite Element Analysis (FEA) method is the most dominant numerical technique in modern engineering, with special regard to the design and analysis of complex structures, including optimization. By dividing large systems into small, viable components or ‘elements’, it is possible to make analyses of complex geometries and material behaviors subject to ease. When it comes to pipeline engineering, FEA ensures the structural integrity, safety, and efficiency of pipelines conveying fluids and gases over vast distances. In this respect, the paper covers the basics of FEA and their application toward pipeline engineering.

Basics of Finite Element Analysis (FEA)

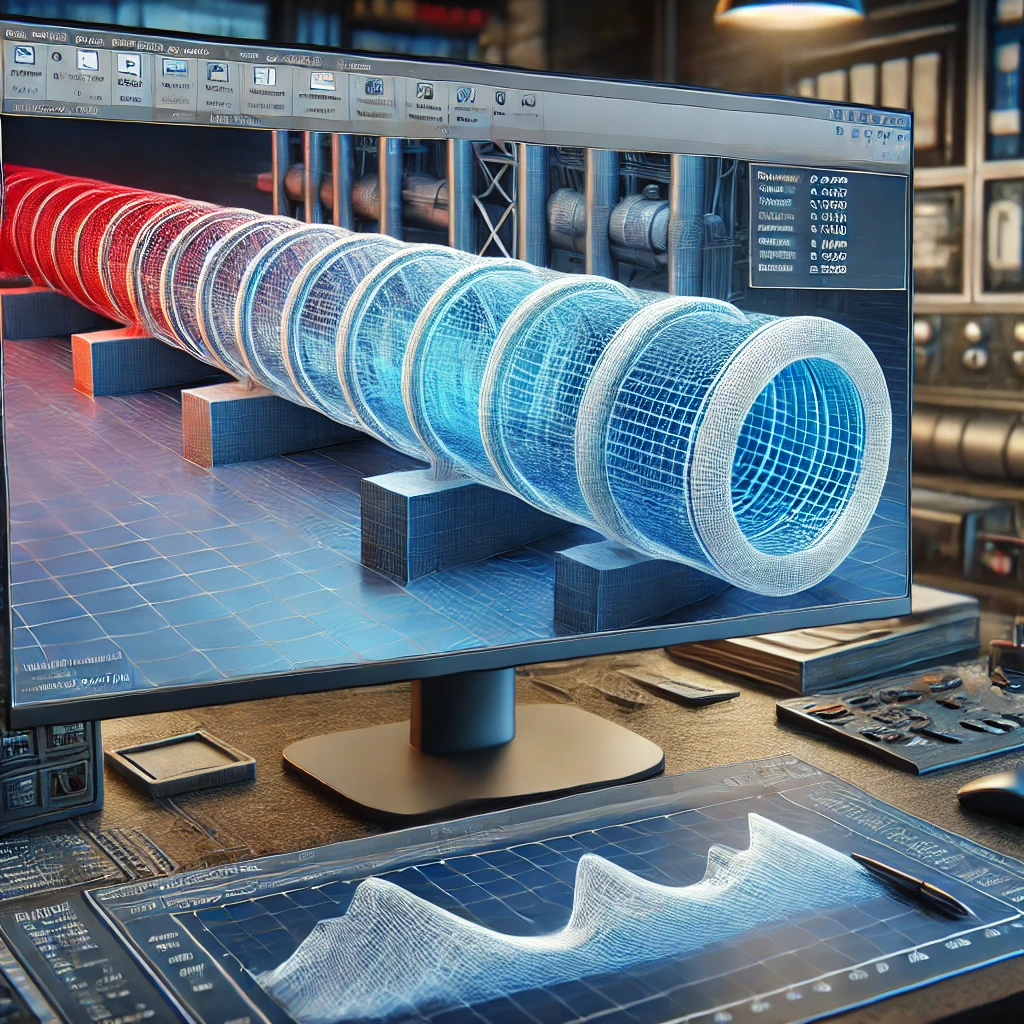

FEA is based on the basic principles of mathematics, physics, and engineering. It is usually done by discretizing a complex structure into a mesh of finite elements connected at nodes. From simple equations, the material and structural physical behavior, according to many diverse conditions, is governed by simplified equations for each element.

FEA gives a detailed view of how the whole system will react to external forces, pressure, changes in temperature, and everything else by solving these equations across every element.

The basic sequence of FEA is:

- Pre-processing: During the initial stage of solution methods, the problem is defined—geometry of the pipe, material properties, boundary conditions, and loading scenarios; afterward, the structure is meshed into a finite element.

- Solution: The finite element model can be solved by appropriate mathematical methods, which are generally based on matrix manipulations to solve a large set of equations simultaneously.

- Post-processing: The output from the analysis is interpreted and visualized using stress, strain, and displacement contours, most often checking how the pipeline is performing under given conditions.

How FEA is applied in Pipeline Engineering

The scope in pipeline engineering involves the choice of material, stress analysis, thermal effects, and fluid dynamics together with the influence of the environment. FEA is used at various points throughout the design and operational life of a pipeline to tackle such problems.

- Structural Integrity Analysis

One of the major applications of FEA in pipeline engineering deals with structural integrity. The inherent features of pipelines have identified them as very likely to be exposed to many load configurations, such as internal pressure applied by the conveyed fluid, external pressure by outside forces, thermal expansion or contraction, among others. FEA aids engineers in predicting how these loads may affect a pipeline’s structural integrity, locating potential failure points, and availing a chance for design modifications prior to construction.FEA can be simulated with different loading conditions as follows:- Internal pressure: This is needed to evaluate the hoop and longitudinal stress within the walls of the pipe.

- External loads: These include soil pressure, live load by vehicles or machinery, and even seismic activity.

- Thermal loads: The pipeline would very commonly be used for carrying fluid at high temperature, and that induces thermal expansion capable of causing severe stresses.

- Fatigue and Fracture Analysis

Cyclic loading of pipelines is, in fact, quite common because of changing pressure levels and temperature variations under varying environmental conditions. Material fatigue will be developed and finally cause fracture because of these accumulated cyclic loads. Fatigue analysis by FEA applies a lot of repetitive stress cycles that could affect a pipeline through its lifetime.The outcomes from the analysis help in predicting the fatigue life of a pipeline and critical locations where initiation of cracks is more likely. Using tougher materials, modifying pipeline geometry, or implementing protective coatings, engineers can subsequently design appropriate mitigation strategies to extend the life of a pipeline. - Buckling Analysis

This is one of the critical failure mechanisms concerning pipelines, particularly buried ones or those under some form of axial compression brought about by thermal expansion or some other form of loading. Buckling characteristics in a structure are often assessed through FEA; using it, different loading conditions can be imitated, and which critical conditions might cause buckling can be determined.FEA may be used to design pipelines in which the elements are sufficiently stiff and stable for the results to withstand even the worst case of buckling. Buckling is a problem with offshore pipelines, on which there will be substantial external pressure brought by an ocean environment. - Thermal Analysis

Pipelines used for transportation of hot fluids or gases result in the generation of thermal gradients along the length, giving rise to thermal stress and deformation. FEA can enable thermal analysis—that is, assessment of the temperature distribution and its influence on the structural integrity of pipelines. This analysis helps to design pipelines that should carry out the thermal expansion without creating stress concentration at the joints. Sometimes, the FEA may demand recommendations of thermal insulation or expansion joints. - Vibration Analysis

Pipelines can vibrate through fluid flow, external forces, or moving mechanical equipment. Such vibrations, if not controlled carefully, can lead to resonance, fatigue, and failure of the pipeline. FEA is executed on a vibration-analysis basis, to identify the natural frequencies of the pipeline and check for potential resonance at different operating conditions.Understanding the vibration characteristics of the pipeline would allow the engineer to suggest some modifications in the design to minimize the danger of vibrational failures. - Corrosion and Erosion Analysis

The environmental conditions and harsh nature of transported fluids make the pipelines prone to corrosion and erosion. FEA can be used along with corrosion and erosion models to make predictions about how materials will degrade over time. These findings help engineers quantify the remaining life of the pipeline so that maintenance activities can be planned. Moreover, FEA can be used to devise protective measures, for example, selecting materials that are corrosion-resistant, the application of coatings, or use of a cathodic protection system to prolong its operational lifespan.

Advancements in FEA for Pipeline Engineering

As the power of computational abilities and software capabilities advanced, FEA became more intricate and achievable. Modern FEA tools can address much more complex geometries, material behaviors, and loading conditions with a high level of accuracy and efficiency.

Conclusion

Finite Element Analysis is an important technique in pipeline engineering that allows getting the most important insights for the safety, reliability, and effectiveness of pipeline systems. Besides, it enables specific analysis on structural integrity, fatigue, buckling, thermal effects, vibrations, and corrosion, which provides for an enabling platform for pipeline design optimization while ensuring potential risks are averted before they become critical. With increasing demands, therefore, on the pipeline infrastructure, FEA will always remain a harbinger of new engineering tools that will innovate for pipeline design and safety.