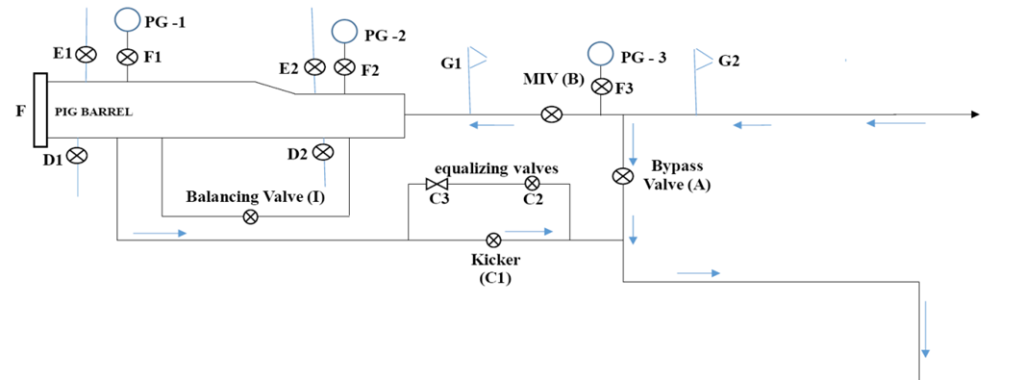

A Pig Trap is an ancillary item of pipeline equipment, comprising a barrel, end closure and instruments, for introducing a pig into a pipeline or removing a pig from a pipeline. Pig Traps are classified into two (2) types based on their Operational and Functional aspects, one is Pig launcher and other is Pig Receiver.

Pig launchers are used to launch the pig into the pipeline, and Pig receivers are used to receive the pigs after they have made a successful run. The design of these pig traps will depend on the type of pig to be run and pipeline design conditions. These designs are not covered here. However, Provisions in the station design should include handling equipment for pigs 12 inch and larger. Caution should be taken for liquid spillage from the pig traps.Pig Trap systems shall be fenced (either separately or as a part of adjoining facilities) and access should normally be provided for Light Trucks and Lifting cranes subject to Hazardous area classification constraints. Within the Pig Trap system plot, where the buried pipelines are less than 1 m below the surface, barriers or other protective measures should be used to prevent vehicles damaging the pipeline.

Components

The main components of pig traps are:

- Major barrel: An enlarged section of the barrel used for loading or retrieving pigs.

- Minor barrel: A section of the barrel between the pig trap valve and the reducer.

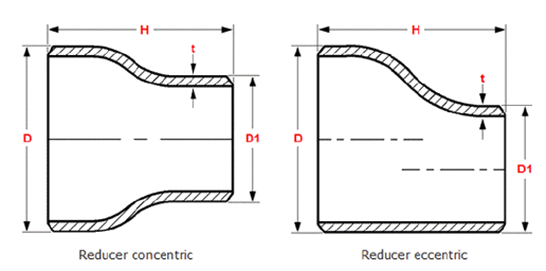

- Reducer: A reducer connects the major and minor barrel

- Types of reducers:

- Concentric

- Eccentric

- Types of reducers:

- Vents

- Drain Valves

- End closure: A quick opening end closure welded to the major barrel allowing the insertion and removal of pigs.

- Pressure gauges: Important safety measures that give operators a clear idea if the pig trap is pressurized or not.

- Bypass line: Connects the pipeline with related upstream/downstream facilities such as a booster station, tank farm, etc.

- Kicker line: Connects the major barrel with the bypass line to enable diversion of the fluid through the barrel to launch or receive a pig.

- Balance valves/lines: Connects the front of the pig trap (minor barrel) to the kicker line. It is controlling the differential pressure; hence, controlling the pig movement.

- Pig signalers: Mechanical or digital devices that actuate when the pig passes through them.

How do pig launchers and receivers work?

The exact procedure for operating a pig launcher or pig receiver will vary somewhat depending on the pigging system being used. However, for the most part it will include the following steps:

Launcher:

- Pipeline operator should make sure that the isolation valve and kicker valve are closed.

- If the system is a liquid system, then the drain valve and vent valve should then be opened to allow air to displace the liquid; if the system is a gas system, then the vent should be opened so that the launcher reaches atmospheric pressure.

- After the pig launcher is completely drained to 0 psi, with the vent and drain valves still open, the trap door should then be opened.

- The pig should then be loaded with its nose in contact with the reducer.

- Closure seals and other sealing surfaces should be cleaned and lubricated as needed and then the trap door should be closed and secured.

- The drain valve is then closed, and the trap is slowly filled by gradually opening the kicker valve.

- Once filling is complete the vent valve is closed so that the pressure will equalize across the isolation valve.

- The isolation valve is then opened, and the pig is ready for launching.

- Next the main valve is gradually closed, increasing the flow through the kicker and behind the pig until finally the pig leaves trap altogether and enters the pipeline itself.

- After the pig leaves the launcher, the mainline valve is fully opened, and the isolation valve and kicker valve are closed.

Receiver:

- The receiver should be pressurized.

- The bypass valve should be fully opened.

- The isolation valve should be fully opened, and the mainline valve partially closed.

- Once the pig arrives the isolation and bypass valves should be closed.

- The drain valve and vent valve are then opened.

- Once the trap is fully depressurized to 0 psi the trap can be opened and the pig removed.

- The closure seal and other sealing surfaces should be cleaned and lubricated as needed and the trap door should then be re-shut and secured.

- The receiver should then be repressurized and returned to its original condition.

These processes may differ somewhat on different systems and of course if the launcher will be launching multiple pigs, then they should all be loaded at the loading stage.

Why Are Pigs, Pig Launchers and Receivers Important?

There are four main benefits for using pigs:

Separation – Pigs can be used to physically separate different products within a pipeline. Without pigs the pipeline would need to either be flushed out between products, or a portion the second product would be contaminated with the first product. Both options would result in waste. With pigs acting as separators, however, this problem is eliminated.

Cleaning and Maintenance – Pigs clean the pipeline by scraping away building up and debris and pushing it safely into the receiving trap. This improves the efficiency and flow of the pipeline and helps prevent corrosive damage to the pipes.

Inspection – Smart pigs using technologies such as MFL and ultrasonics can inspect the pipeline for welding defects, cracks, pitting, and other problems. Caliper pigs can also take estimates of the internal geometry of the pipeline.

Positioning and monitoring – Smart pigs not only inspect and retain the data about the pipeline, but they can also provide information about where the defect or trouble area of the pipeline is located. This prevents unnecessary digging up of healthy parts of the pipeline and if a problem isn’t severe enough to warrant replacing, it also allows the trouble section to be closely monitored and the pig results to be compared across multiple time frames to track damage progression.