A barred tee, also known as a pigged tee, is a specific type of fitting used in pipelines that are pigged. The term “pigging” refers to the practice of using devices known as “pigs” to perform various maintenance operations on a pipeline without stopping the flow of the product in the pipeline.

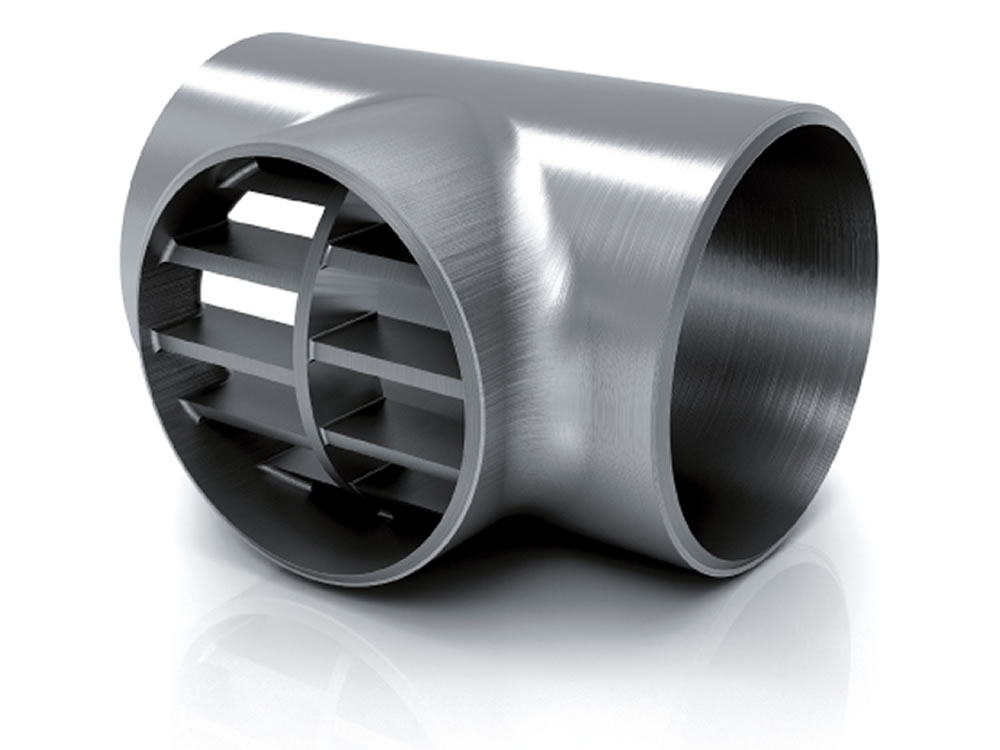

Barred tees are designed with a restriction bar welded internally to prevent the pig from traveling down a branch connection. These bars are installed flush with the inside diameter of the pipeline to prevent the pig from hanging up when it passes through. The bars should be made of a similar or identical material as the parent material.

The size of the bars on the tee should be small enough so that they do not restrict the flow from the branch connection. However, they should be large enough to prevent breakage based on the flow rate through the branch connection of the tee.

Barred tees are pipe fittings with two outlets, one at 90 ° to the connection to the main line that has tiny holes. They can either be extruded or fabricated and are used to connect two pieces of pipe or fittings.

The shape of a barred tee is like a butt-welding pipe tee with some bars in the branch of the tee. The bars are used for preventing the pig from running out in the branch of the main pipe. It is commonly used in a pigged pipeline, so it is also called pigged tee.

Tees Vs. Barred Tees

- Tee (Standard Tee):

- A Tee is a common pipe fitting used to combine or divide fluid flow.

- It allows fluid to flow on its main pipe and branch out.

- Two types of Tees exist: Equal Tee (branch size equals main pipe size) and Reducing Tee (branch size smaller than main pipe size).

- Standard Tees follow international standards like ASME B16.9 or MSS-SP 75.

- They are not specifically designed for pigging operations.

- Barred Tee (Pigged Tee):

- Barred Tees are specialized Tees used in pigged pipelines.

- They have bar plates inside the branch outlet (resembling a steel cage) to restrict pipeline pigs (used for cleaning or inspection) from flowing into branch pipes.

- Design codes for Barred Tees are custom-made based on ASME B16.9 or MSS-SP 75 Tees, often following Shell DEP 31.40.10.13-Gen or ISO 15590-2 standards.

- Bar plates prevent pigs from changing direction or getting stuck at the branch outlet.

- Smoothness is crucial for pigging; the opening in the branch pipeline after guided bars should not exceed 40% of the main pipeline area.

- Bar size must allow flow while sustaining pressure.

- The pigging process must be smooth to protect pig sensors.

In conclusion, barred tees play a crucial role in maintaining the efficiency and safety of pigged pipelines. By preventing pigs from entering branch connections, they ensure the smooth operation of the pipeline and protect both the pipeline and the pigs from potential damage.