Valves are devices used to regulate fluid flow by opening, closing, or partially obstructing the passageway. There are various types of valves such as gate, globe, butterfly, needle, and diaphragm valves. We use the following International Standards:

- API 6A: Specification for Wellhead and Tree Equipment

- API 6D: Specification for Pipeline and Piping Valves

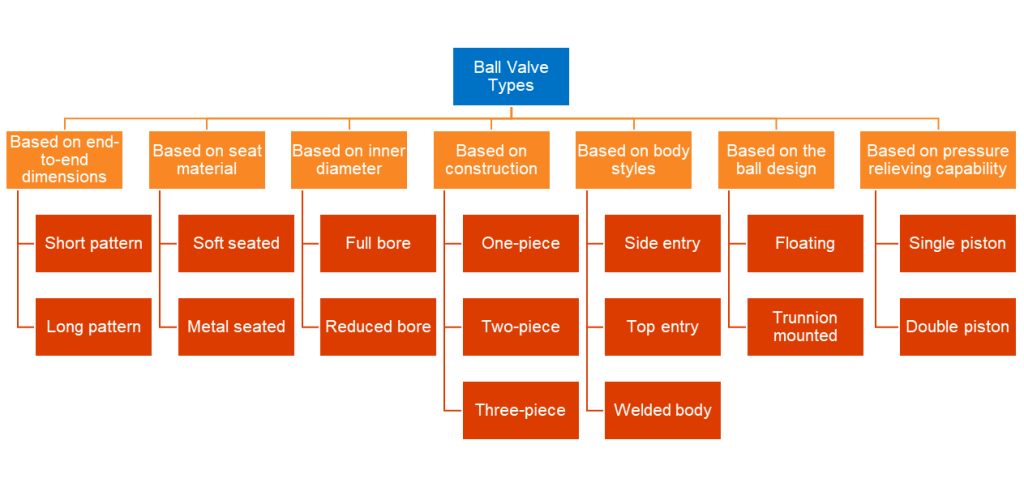

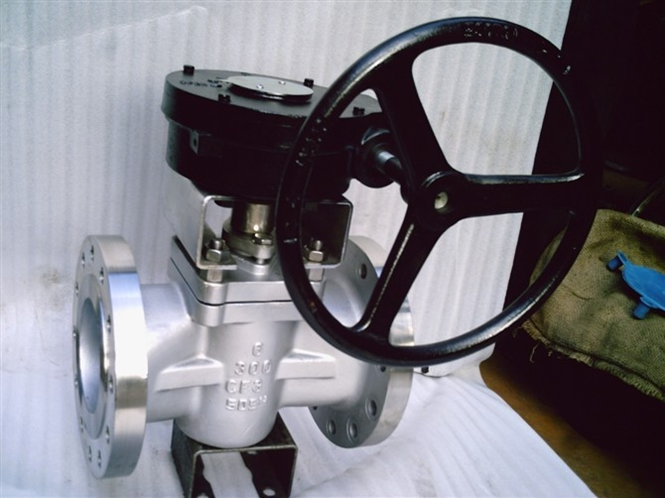

Ball valves are the most common and are mainly used for hydrocarbon service. They can be operated locally, remotely, or automatically depending on the leak and release volumes. The following chart shows the various types of ball valves:

Globe Valve: A globe valve is an instrument used to stop and/or control the flow of fluids in a pipeline. It works by halting the flow of a fluid through a pipe. The name globe comes about due to the valve’s cylindrical shape.

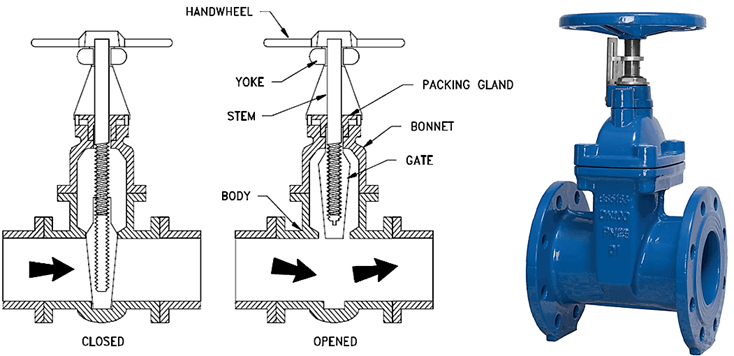

Gate Valve: A gate valve has a sliding gate or wedge that moves perpendicular to the flow direction. It is primarily used for on/off control.

Needle Valve: Needle valves, sometimes referred to as plunger valves, are regulating valves and enable engineers to finely control and regulate water flow and pressure.

Butterfly Valve: A quarter turn valve used to shut on/off the follow by using a disc to control flow. Gate and butterfly valves are both used to turn on and off the flow, but butterfly valves can also regulate flow via partial disc closure. Butterfly valves are part of the quarter-turn family of valves and can be shut off much faster than gate valves, which are multi-turn valves.

Check Valve: one-way or nonreturn valves that open with fluid movement and pressure, and close to prevent backflow of the pressure to upstream equipment such as pumps and compressors. In fact, check valves allow the fluid to flow in only one direction.

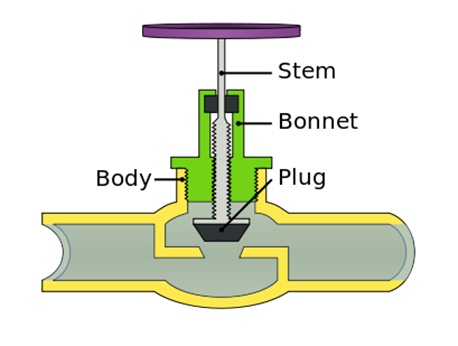

Plug Valve: A plug valve is based on a plug with a hollow passage in the valve body. The quarter-turn motion creates an alignment between the pipe and the hole, leading to an open state. When turned to a 90-degree angle from the open position, the valve sits across the pipe leading to a closed state.

Apart from regulating the flow, in pipeline engineering, valves are used also to serve the following roles:

- Block Valve: A valve for interrupting the flow or to shut-in a section of a pipeline, A block valve is normally either fully open or fully closed.

- Emergency Shutdown Valve: Valve used for isolating a pipeline from a source or destination in case of emergency situations.

- Isolation Valve: Valve used to interrupt the flow or to isolate one section of a pipeline from an adjacent section or a facility connected to the pipeline. An isolation valve is normally either opened or fully closed. Isolation valves are sometimes referred to as block valves.

- Overpressure Protection Valve: Valve intended to protect the pipeline against overpressure by preventing pressure from a source building up in the pipeline.

- Pressure Relief Safety Valve: Valve for protecting a pipeline against overpressure by releasing fluid from the pipeline.

- Sectionalizing Block Valve: Main valve for sectionalizing a pipeline, to limit the release of line contents in case of pipeline leak or rupture.

- Surface Safety Valve: Valve, part of the well-head assembly, applied as isolation valve between flowline and wellhead.

Valve Actutation

- Block valves can be operated locally, remotely, or automatically depending on leak and release volumes.

- Automatic valves can be activated by low pressure, increased flow, rate of loss of pressure or a leak detection system.

- Automatic valves should be fail-safe to close.

- Valve actuators and gearboxes should be sized properly, and shear pins should be fitted to prevent damage.

- The process safeguarding system should actuate the emergency shutdown valves when an emergency shutdown condition occurs.

Engineering Guidelines

- For pipelines with a permanent pigging facility, all main line valves and the first isolation valve on branch/bypass line shall be full bore. However, pipelines not designed for operational pigging, the mainline valve shall be full bore valve and the branch / bypass valves could be reduced bore.

- Careful choice of valve type shall be taken to isolate pig traps. The selection is based on the below:

- Single Block & Bleed = Sweet/Sour Service and 600# & Below Flange rating

- Double Block & Bleed = Sour Service and 900# & Above Flange rating