What are gaskets?

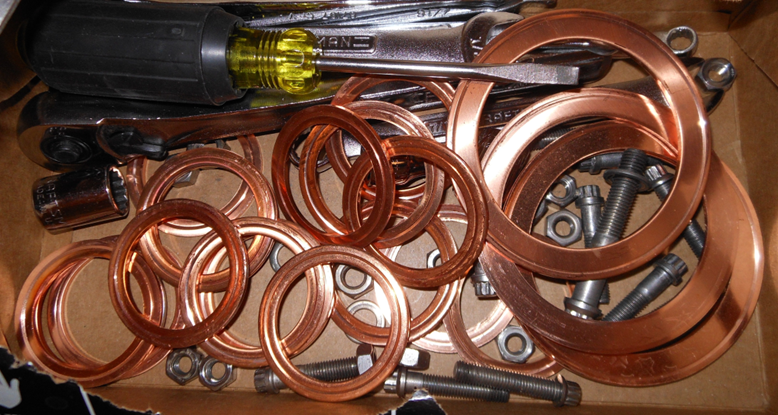

A gasket is a seal that fills the space between two or more mating surfaces. Its purpose is to prevent leakage of gases or liquids. Gaskets are typically made from flexible materials like rubber or metal, allowing them to conform to the shape of the mating surfaces and create a tight seal.

Types of Gaskets

In pipeline engineering, gaskets play a crucial role in ensuring leakproof sealing between connecting flanges:

- Non-Metallic Gaskets: These are made from materials like graphite, rubber, Teflon, and compressed non-asbestos fiber (CNAF). They are cost-effective and suitable for low-pressure and low-temperature applications. Full-face gaskets work with flat-face (FF) flanges, while flat ring gaskets suit raised-faced (RF) flanges.

- Metallic Gaskets (Ring Joint Gaskets): These robust gaskets are crafted from materials like soft iron, low carbon steel, stainless steel, Monel, or Inconel. They’re used in high-pressure and high-temperature scenarios (above 900 Class). Metallic gaskets require high-tension bolting and fit into grooves on mating flanges.

- Composite Gaskets: These combine metal and non-metal materials. Examples include spiral wound, metal jacketed, and camprofile gaskets. They offer a balance of cost-effectiveness and performance across a wide range of pressure and temperature services.

Gasket Guidelines

Materials should be selected such that they are suitable for all the expected service conditions. The following are some specific considerations in accordance with ASME B31.3:

(a) Gasket materials not subject to cold flow should be considered for use with raised-face flanges for fluid services at elevated pressures with temperatures significantly above or below ambient.

(b) Use of full-face gaskets with flat-faced flanges should be considered when using gasket materials subject to cold flow for low pressure and vacuum services at moderate temperatures. When such gasket materials are used in other fluid services, the use of tongue-and groove or other gasket-confining flange facings should be considered.

(c) The effect of flange facing finish should be considered in gasket material selection

| Flange Facing | Gasket Type |

| Flat Face – FF | Soft/Non-metallic |

| Raised Face – RF | Non-metallic / Semi metallic |

| Ring type joint – RTJ | Hard / metallic |

Bolting

Bolting includes bolts, bolt studs, studs, cap screws, nuts, and washers. They are used to secure flanges, valves, and other components in piping systems. They ensure leak-proof connections between gaskets and flanges. There are many types of bolts, but the most common type in use is stud bolts. The number and dimensions of the bolts to be used is standardized and the material of construction shall match that of the joined component.