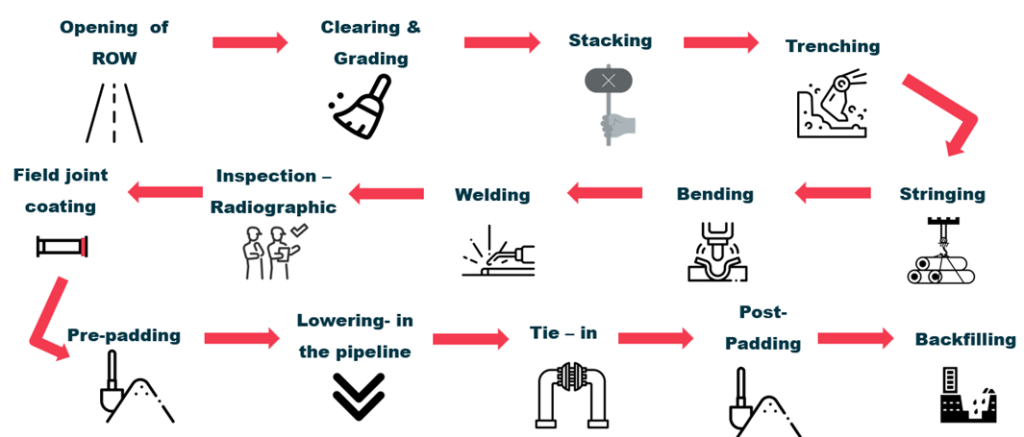

What are the stages in pipeline construction?

The construction stages for a pipeline may vary from a country to another. However, the typical construction sequence for buried pipelines is as follow:

- Right-of-Way designation

- A specified zone of land within which the pipeline operator has the right to conduct pipeline building, functioning, and upkeep activities in accordance with the landowner’s agreement.

- It is surveyed, cleared of brush and trees, and levelled to give workers and equipment access to build, inspect and maintain the pipeline.

- Clearing & Grading

- Grading refers to the removal and disposal of snow, rocks, sand dunes, tree stumps, and roots.

- Clearing refers to the process of cutting and disposing of trees. Farm crops, bushes, and undergrowth

- The right-of-way will be graded, and ice and snow or gravel pads will be built to allow for the movement of ditchers, additional equipment, materials and other pipeline construction activities.

- Stacking

- Stacking refers to marking the pipeline’s centreline with visible markers.

- Trenching

- To bury the pipeline, a trench or ditch is required. The method of excavation and the choice of equipment depend primarily on the soil type.

- Options include bucketwheel trenchers, as seen on the Norman Wells pipeline, and chain trenchers, employed for the Ikhil pipeline. Additional excavation tools include backhoes.

- The width of the trenched area shall be equivalent to the OD of the pipeline plus 300 mm on each side.

- Crossings:

- Throughout a pipeline route, crossings of rivers, streams, roads, and other pipelines are carefully planned in advance.

- Water crossings are typically accomplished using either ‘open cut’ methods or horizontal directional drilling.

- The choice of crossing method is determined by specific site factors such as fish habitats, water flow dynamics, and soil conditions including rocks and boulders.

- Horizontal directional drilling is generally preferred for significant river crossings, where local soil conditions allow.

- Stringing

- Stringing refers to the process of laying the pipes carefully on wooden skids or sandbags closer to the trench along the right-of-way, ready for welding.

- Bending

- There are three types of bends:

- Hot bending: As the name indicates, the pipe is heated to a certain temperature and then bent. This type is normally performed at the factory.

- Cold bending: Sometimes referred to as field bending, this type is performed at site using a bending machine without heating the pipe.A specialized pipe-bending machine is used to bend some pipe to the shape of the land. The pipe retains its strength and remains circular where it is bent because of the characteristics of steel and the bending techniques used.

- Elastic bending: This type refers to the small bends incurred by the pipeline due to elevation changes in the route. The bending is within the elastic zone of the pipeline.

- If there is any field bending that might take place, it is done at this stage.

- There are three types of bends:

- Welding

- Welding involves melting another metal to join lengths of pipe. The welded area, intentionally stronger than the pipe itself, results from this process. This procedure is iterated until several pipe sections unite to create a pipeline. Automatic welding machines are preferred, with some manual welding also employed. A meticulous quality assurance and control program is rigorously adhered to, ensuring the welding’s strength and quality.

- Common types of welding used are Shielded Metal Arc Welding SMAW, Gas Metal Arc Welding GMAW.

- Inspection

- X-ray testing of welded joints and welded material testing are essential stages in pipeline construction. They help identify defects within the welded materials.

- Field Joint coating

- Each welded joint must be protected by applying a heat shrink sleeve.

- Pre-padding

- The bottom of the trench shall be pre-padded using a soft material, usually sand, to a certain height of the trench before lowering in the pipes.

- Lowering-in

- After ensuring the previous activities have been completed, the welded line pipes shall be lowered in the trench using sidebooms. The number, distance, and type of sidebooms for lowering in shall be carefully investigated prior to lowering in.

- Tie-in

- Valves, including shut-off valves that can block off sections of the pipeline for maintenance, and other connections are installed as the pipeline is constructed.

- If there are other pipeline tie-ins, they normally take place at this stage inside the trench prior to post padding.

- Post-padding

- The pipeline shall be post padded with sand to a minimum of 300 mm from the crown of the pipeline.

- Backfilling

- The initial material that was removed during the trenching stage shall be backfilled to cover the pipeline and establish the windrow.

- Sometimes the excavated soil is used to fill the trench and sometimes other selected backfill is used. Care is taken to protect the pipe coating from potential damage.