What is pipeline engineering?

In order for us to explore the essence of pipeline engineering, we first must define a pipeline itself. A pipeline is a network of pipes and associated elements designed to convey fluids between plants, excluding the plants themselves. The pipeline spans from one pig trap to another (including the pig traps), or if no pig trap is installed, it extends to the initial isolation valve within the plant boundaries, or another designated valve further inside.

Pipelines serve essential roles in transporting various substances like petroleum, water, chemicals, foodstuffs, pulverized coal, and gases such as natural gas, steam, and compressed air. It’s crucial for pipelines to be completely sealed to prevent leaks and capable of withstanding the necessary pressure to propel the conveyed materials. These pipelines are constructed using a diverse range of materials, with diameters spanning from a fraction of an inch to as wide as 30 feet. Common materials include steel, wrought and cast iron, concrete, clay products, aluminum, copper, brass, cement-asbestos, plastics, and wood.

The pipeline system includes fittings (valves and joints), pumps (compressors or blowers in the case of gas pipelines), booster stations, storage facilities connected to the pipe, intake and outlet structures, flowmeters and other sensors, automatic control equipment including computers, and a communication system.

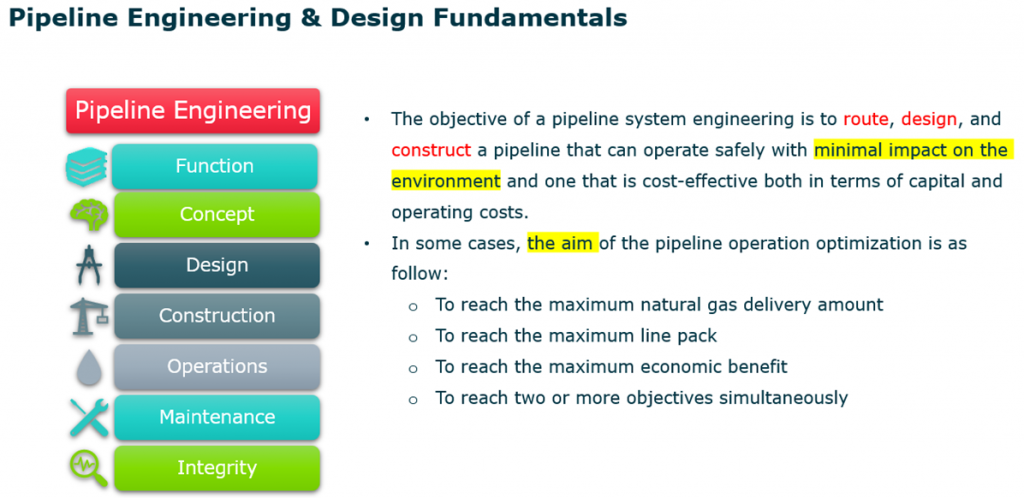

The objective of a pipeline system engineering is to route, design, and construct a pipeline that can operate safely with minimal impact on the environment and one that is cost-effective both in terms of capital and operating costs.

In some cases, the aim of the pipeline operation optimization is as follow:

- To reach the maximum natural gas delivery amount

- To reach the maximum line pack

- To reach the maximum economic benefit

- To reach two or more objectives simultaneously

- Minimize the Cost of the construction considering mainly crossings, type of terrain and constructability

- Minimize the Cost of the Material considering overall length of the pipeline

- Minimize the Environmental Impact

- Minimize Operational Risk

What is the orientation of the pipeline industry?

The pipeline industry plays a crucial role in the transportation of petroleum and natural gas. In the United States, for example, pipelines transport 66% of the petroleum consumed. Pipeline workers undergo comprehensive orientation to learn a broad range of safe work practices and prepare for hazards they will encounter in the pipeline industry. The pipeline and process services market, which includes activities throughout an oil and gas pipeline’s life cycle, is projected to grow from USD 3.63 billion in 2023 to USD 5.53 billion by 2030.

What are the associated equipments related to Pipeline Transportation?

- Pipeline transportation systems are equipped with various components to ensure the safe and efficient movement of liquids, gases, and slurries. Here are some of the associated equipment:

- Pumps (Liquid fluids and Slurries):

- Pumps are used to boost the internal pipeline pressure to keep the fluid moving through the pipeline system

- Best suited for incompressible fluids

- Compressors (Gases):

- Compressors are typically packaged with the driver and all auxiliary systems on a base frame for ease of handling and reduced site installation time. They are used in gas pipelines to increase the pressure within the pipe and keep the gas moving

- Best suited for compressible fluid

- Oil and Gas Separators: An oil/gas separator is a pressure vessel used for separating a well stream into gaseous and liquid components. They are installed either in an onshore processing station or on an offshore platform

- Condensate Separation: This process removes water and solid contaminants from condensate

- Injection Water: This process removes solid contaminants and microorganisms which can foul injection wells

- Inlet Separation: This is the bulk solids and liquids removal as pre-treatment for downstream equipment

- These components work together to ensure that the pipeline system operates efficiently and safely

- Pumps (Liquid fluids and Slurries):