Introduction

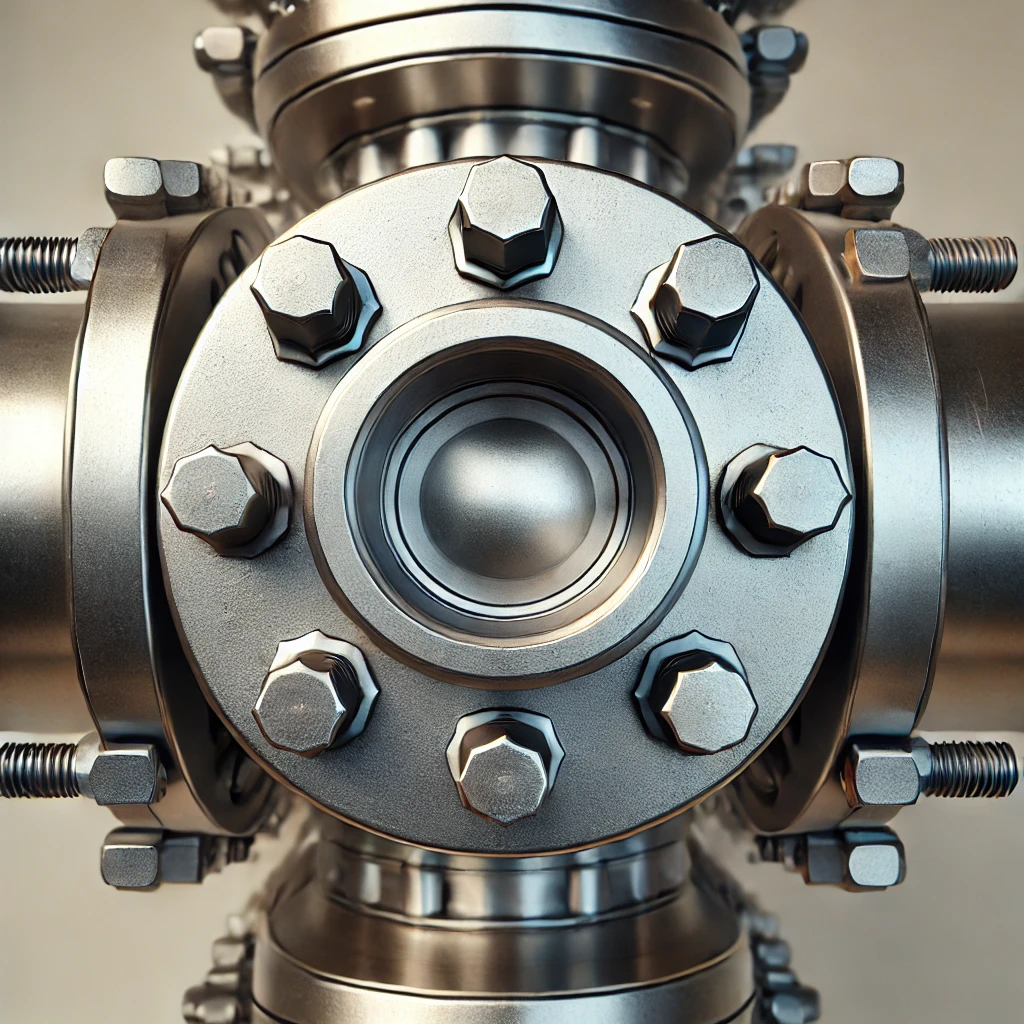

Flanges are critical components in piping systems, serving as the interface between different sections of pipes, valves, pumps, and other equipment. The reliability and safety of these systems largely depend on the proper design and assembly of flanges. One of the most crucial aspects of flange design is the calculation of flange loading, which ensures that the flanges can withstand the forces and pressures they will encounter in operation. This article provides a detailed exploration of flange loading calculation, its importance, and the limitations that engineers and designers need to consider.

Understanding Flange Loading

Flange loading refers to the forces exerted on a flange when it is installed in a piping system. These forces can result from internal pressure, external mechanical loads, thermal expansion, and other operational conditions. The correct calculation of flange loading is essential to prevent failures such as leaks, flange rotation, or even catastrophic rupture, which can lead to safety hazards, environmental damage, and significant financial losses.

Flange loading is typically divided into two main categories:

- Internal Pressure Loading: This occurs due to the pressure of the fluid inside the pipe, which exerts a force on the flange surfaces. The internal pressure tries to separate the flanges, and the bolts and gasket must be capable of resisting this force to maintain a leak-tight seal.

- External Mechanical Loading: These loads are the result of external forces such as pipe weight, wind, seismic activity, or thermal expansion. These forces can act in multiple directions and create bending moments, shear forces, and axial forces on the flange.

Calculating Flange Loading

The calculation of flange loading involves determining the forces acting on the flange and ensuring that these forces do not exceed the capacity of the flange, bolts, and gasket. The following steps outline the general approach to calculating flange loading:

- Identify Operational Conditions: The first step is to determine the operational conditions such as internal pressure, temperature, and external forces. These conditions dictate the magnitude and direction of the forces acting on the flange.

- Select Flange and Gasket Materials: The materials for the flange, bolts, and gasket must be selected based on the operational conditions. The material properties such as yield strength, tensile strength, and thermal expansion coefficients are critical inputs for the loading calculations.

- Determine Internal Pressure Forces: The force exerted by the internal pressure is calculated using the formula:

- Fp=P×A

- Where:

- Fp is the force due to internal pressure,

- P is the internal pressure,

- A is the effective area of the flange.

- Calculate External Mechanical Forces: External mechanical forces can be calculated based on the system design. This includes the weight of the piping system, thermal expansion forces, and any dynamic forces such as vibration or wind loading.

- Compute Bending Moments and Shear Forces: The external loads can create bending moments and shear forces on the flange. These are calculated based on the load distribution and the geometry of the flange and piping system.

- Check Flange, Bolt, and Gasket Stresses: The final step is to ensure that the calculated forces and moments do not exceed the allowable stresses for the flange, bolts, and gasket. This involves checking the stresses against the material properties and applying safety factors as required by design codes and standards such as ASME B16.5, ASME VIII, and others.

Limitations in Flange Loading Calculations

While flange loading calculations are essential for ensuring the safety and reliability of piping systems, they are not without limitations. These limitations can arise from various factors, including assumptions made during the calculations, material behavior, and the complexity of real-world loading conditions.

- Simplifying Assumptions: Flange loading calculations often involve simplifying assumptions to make the problem manageable. For example, uniform pressure distribution is assumed across the flange face, and the effects of localized stresses are often neglected. These assumptions can lead to discrepancies between calculated and actual stresses.

- Material Behavior: The behavior of materials under load is not always predictable. For instance, gaskets can exhibit nonlinear compression characteristics, and flange materials may behave differently under cyclic loading conditions. These factors can affect the accuracy of the loading calculations.

- Thermal Expansion and Creep: High temperatures can cause thermal expansion of the flange and bolts, leading to additional stresses. Over time, materials can also undergo creep, which is a gradual deformation under sustained load. Standard calculations may not fully account for these long-term effects.

- Dynamic Loads: In real-world applications, flanges may be subjected to dynamic loads such as vibration, water hammer, or pressure surges. These loads can cause transient stresses that are difficult to predict and are not always accounted for in standard calculations.

- Gasket Performance: The gasket plays a crucial role in maintaining a seal under load. However, gasket performance can be affected by factors such as creep relaxation, temperature fluctuations, and chemical compatibility with the fluid. If the gasket fails to perform as expected, it can compromise the integrity of the flange joint.

- Non-Uniform Bolt Loading: In practice, achieving uniform bolt preload is challenging. Variations in bolt tension can lead to uneven distribution of flange loading, which can increase the risk of leakage or flange rotation. Standard calculations assume uniform bolt loading, which may not be realistic.

- Environmental Factors: Environmental conditions such as corrosion, temperature changes, and exposure to chemicals can degrade flange materials over time, reducing their load-carrying capacity. These factors are often difficult to quantify and incorporate into flange loading calculations.

- Code Limitations: Design codes and standards provide guidelines for flange loading calculations, but they may not cover all possible loading scenarios. Engineers must use their judgment and experience to account for conditions that are not explicitly addressed in the codes.

Conclusion

Flange loading calculation is a critical aspect of piping system design, ensuring that flanges can withstand the forces they will encounter during operation. However, these calculations have inherent limitations due to simplifying assumptions, material behavior, and the complexity of real-world conditions. Engineers must be aware of these limitations and take appropriate measures, such as applying safety factors, conducting experimental tests, and performing regular inspections, to mitigate the risks associated with flange loading. By understanding and addressing these challenges, it is possible to design safer and more reliable piping systems that meet the demands of modern industrial applications.

In conclusion, while flange loading calculations are indispensable tools for engineers, they should be applied with an understanding of their limitations and supplemented with practical engineering judgment and experience. This approach will ensure that flanged joints remain secure and leak-free under a wide range of operational conditions, thereby safeguarding both the integrity of the piping system and the safety of the personnel and environment.