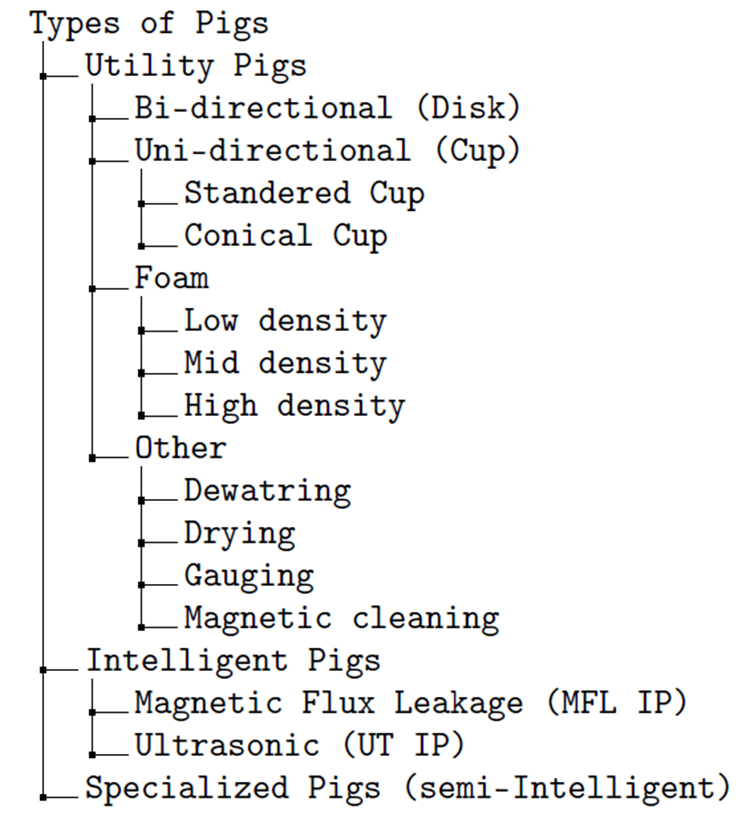

Pigs are generally made of metallic bodies. Bi-directional pigs are typically preferred due to being able to move in both directions, hence easy retrieval.

Cup pigs are of two types:

- Slandered

- Conical

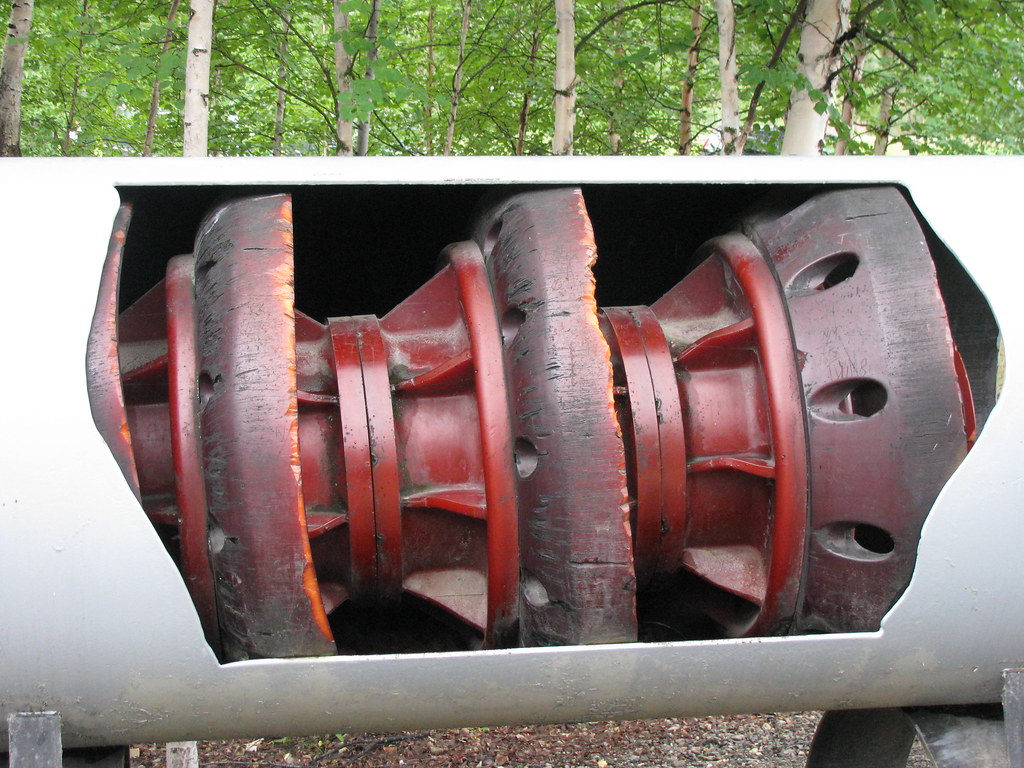

Disk pigs:

- Flat section

- Support disk 99% of ID

- Sealing element 102% of ID

- Bi-directional

- Better performance than cup pig, & easily retrievable

- Minimum bend radius 1.5D

- Preferable

Foam pigs:

- Used to test piggability or retrieval of trapped pig.

- Lowest cleaning performance

- Low risk of blockage (increased pressure will destroy them)

- Inexpensive

Pigging Medium Properties

| Pigging Medium | Liquid | Gas |

| Properties | 1. Generally lower pressure around 30 to 40 bar 2. It’s incompressible so easier to control as there is no significant build-up pressure. 3. Liquid works as a lubrication for the pig which reduces the following: i.Wear ii.Tear iii.Vibrations | 1. Gas has a higher pressure than oil that is more than 120 bar. 2. Due to high pressure, there is reduced controllability considering the compressibility of gases. 3. Gas is considered a harsh and dry medium that will cause greater: i.Wear ii.Tear iii.Vibrations |

Pig Traps Design

The main components of pig traps are:

- Major barrel: An enlarged section of the barrel used for loading or retrieving pigs.

- Minor barrel: A section of the barrel between the pig trap valve and the reducer.

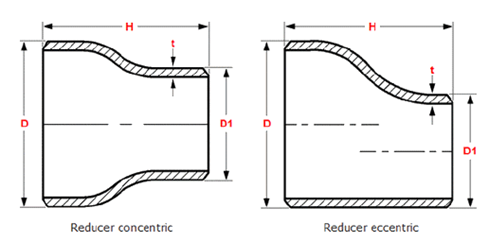

- Reducer: A reducer connects the major and minor barrel

- Types of reducers:

- Concentric

- Eccentric

- Types of reducers:

- Vents

- Drain valves

- End closure: A quick opening end closure welded to the major barrel

- Pressure gauges: Important safety measures that give operators a clear idea if the pig trap is pressurized or not.

- Bypass line: Connects the pipeline with related upstream/downstream facilities such as a booster station, tank farm, etc.

- Kicker line: Connects the major barrel with the bypass line to enable diversion of the fluid through the barrel to launch or receive a pig allowing the insertion and removal of pigs.

- Balance valves/lines: Connects the front of the pig trap (minor barrel) to the kicker line. It is controlling the differential pressure; hence, controlling the pig movement.

- Pig signalers: Mechanical or digital devices that actuate when the pig passes through them.

Design Pressure

(1). The design pressure of the pig trap system shall not be less than that of the pipeline.

(2). Pipeline design pressure and fitting class rating shall be as indicated on the datasheet.

Design Temperature

(1). The maximum design temperature shall not be less than the maximum temperature that the pig trap system could attain or to which it could be exposed during operation, start-up or shutdown.

(2). The minimum design temperature shall be based on minimum ambient temperature and on the conditions that could occur during operations.

(3). Minimum and maximum ambient temperatures shall be as indicated on the datasheet.

Design Velocities

Suggested maximum velocities for the purpose of piping diameter selection are:

- For piping in intermittent service:

- In liquid: 8 m/s (26 ft/s)

- In gas: 40 m/s (130 ft/s)

- For piping in continuous service:

- In liquid: 4 m/s (13 ft/s)

- In gas: 20 m/s (65 ft/s)